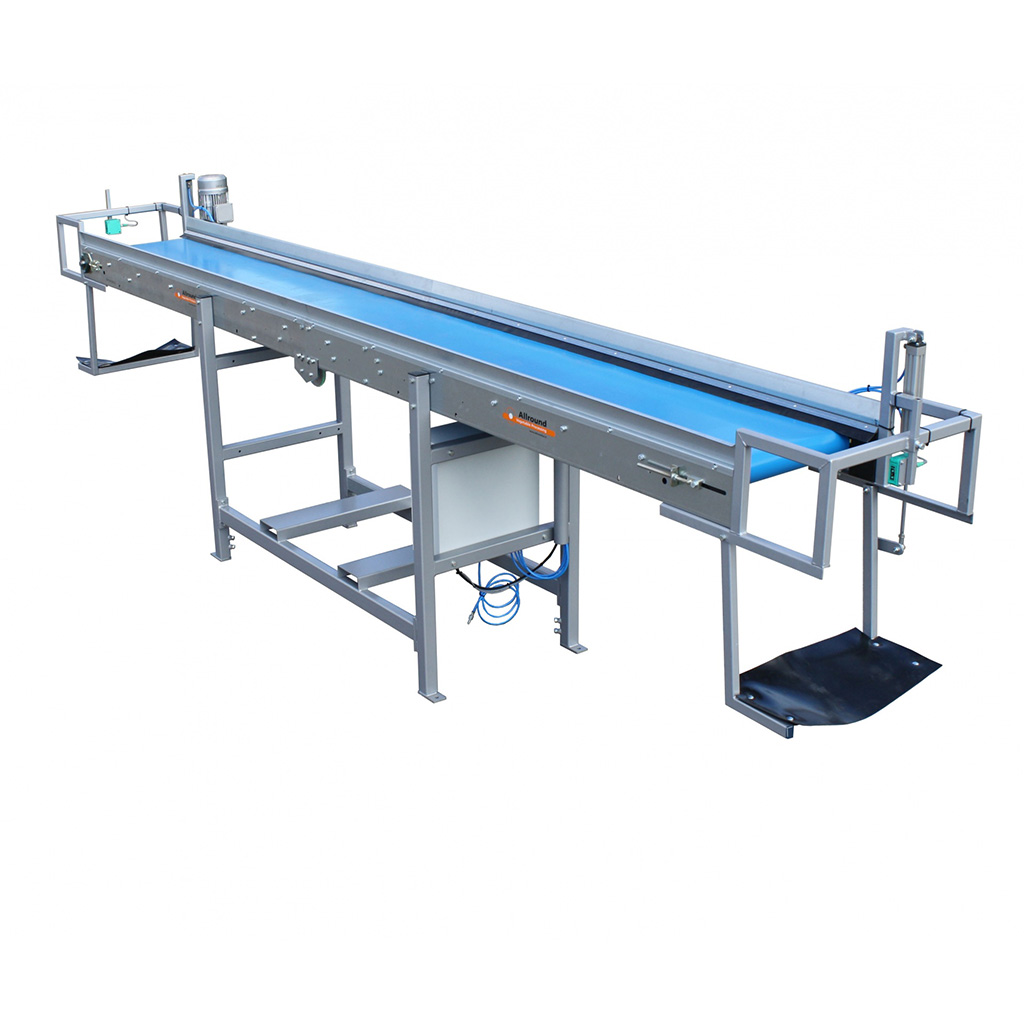

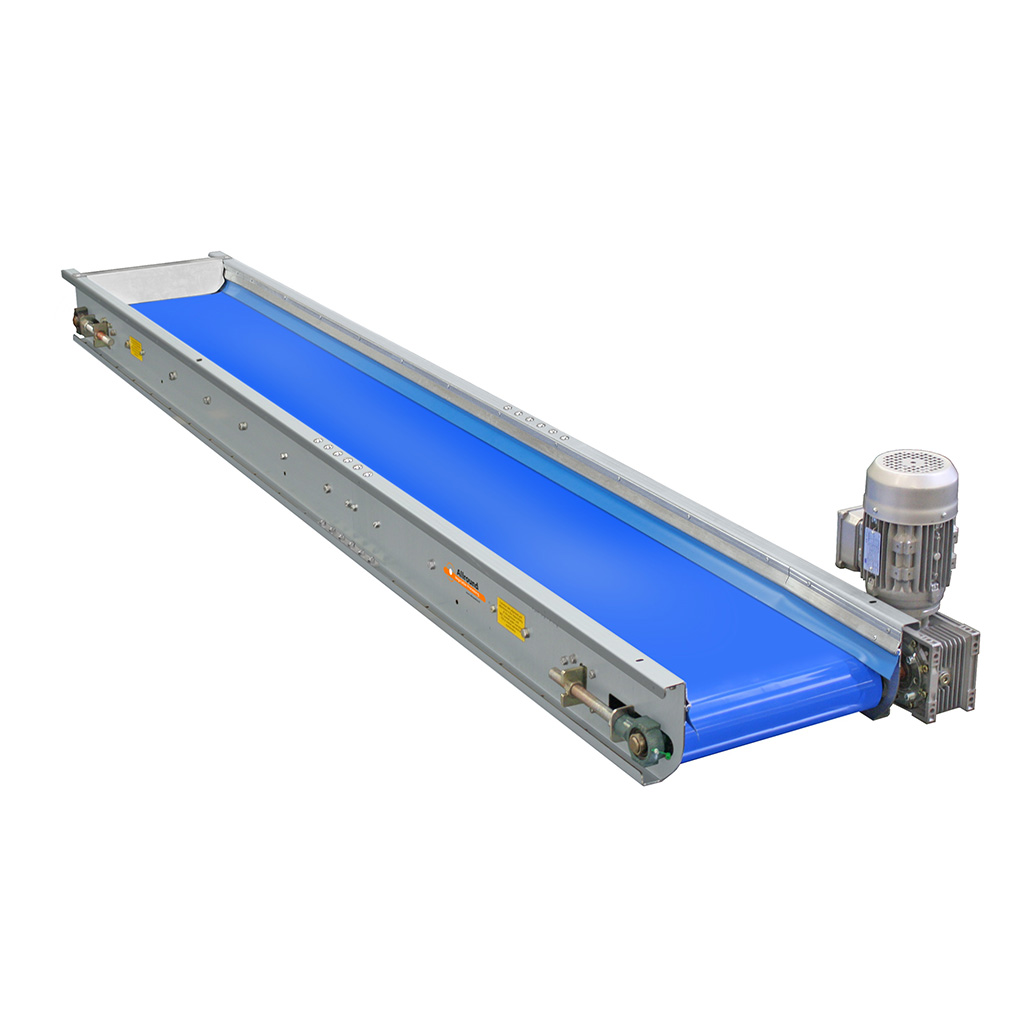

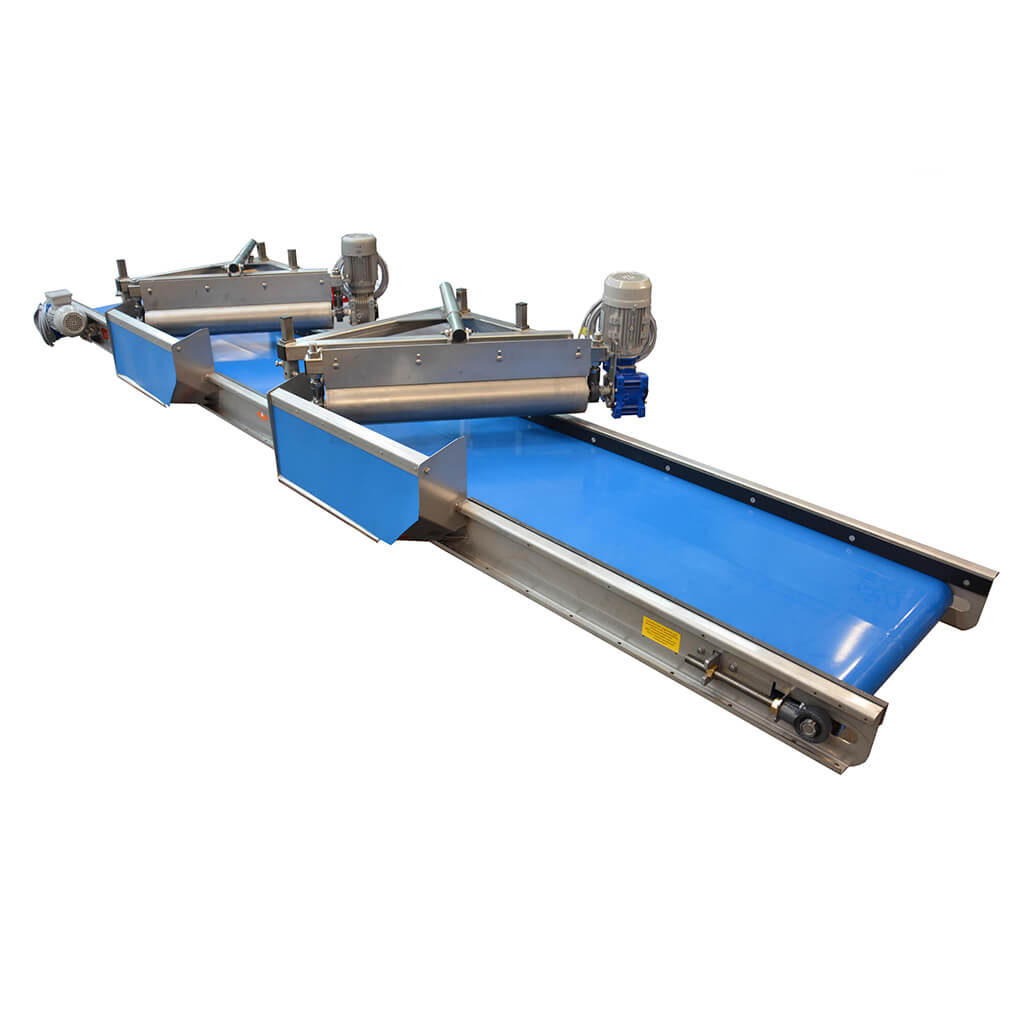

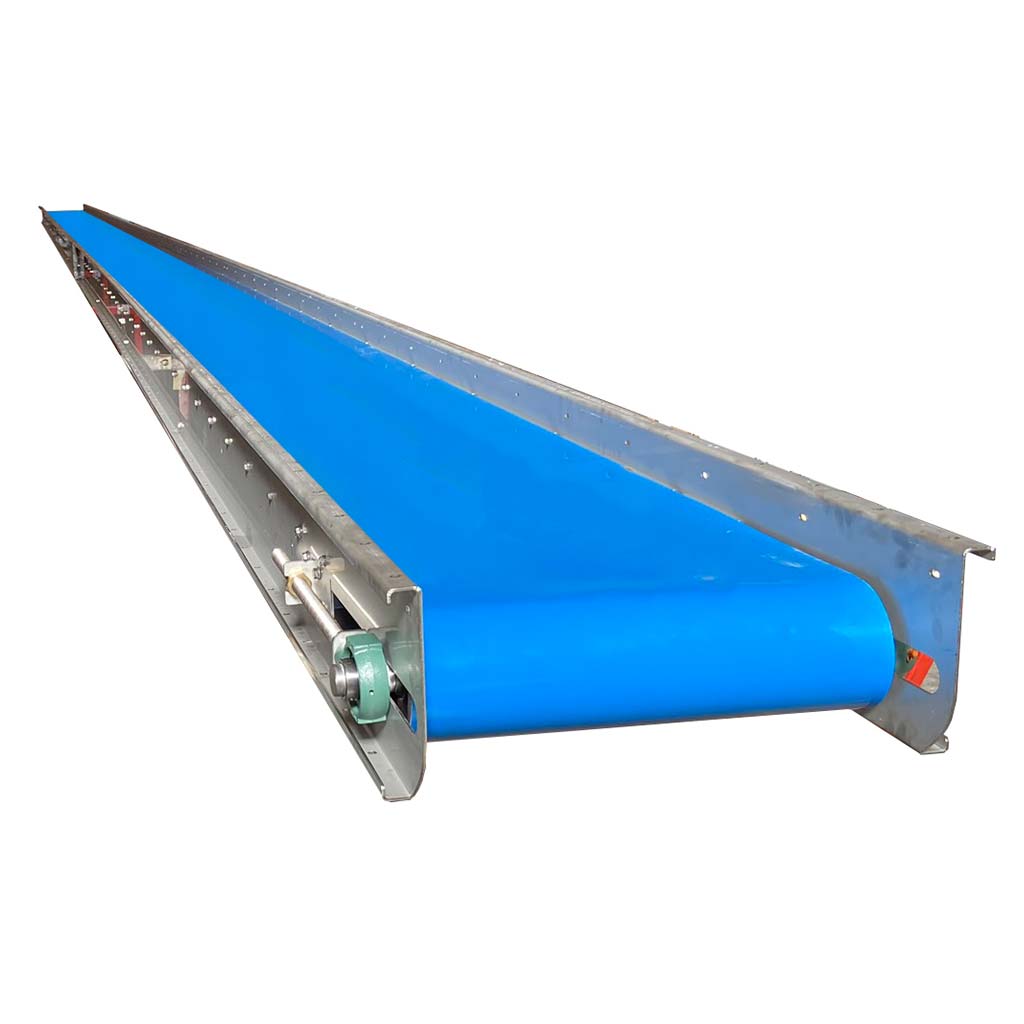

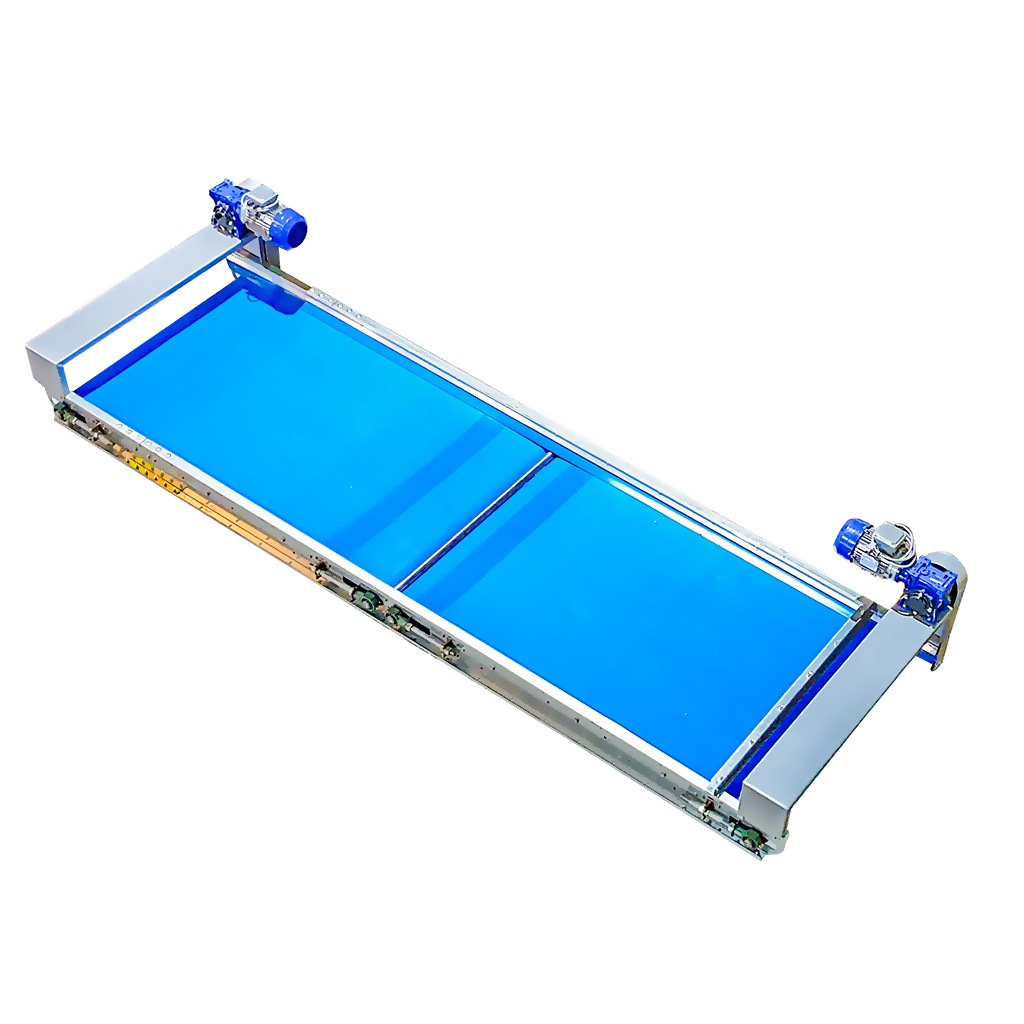

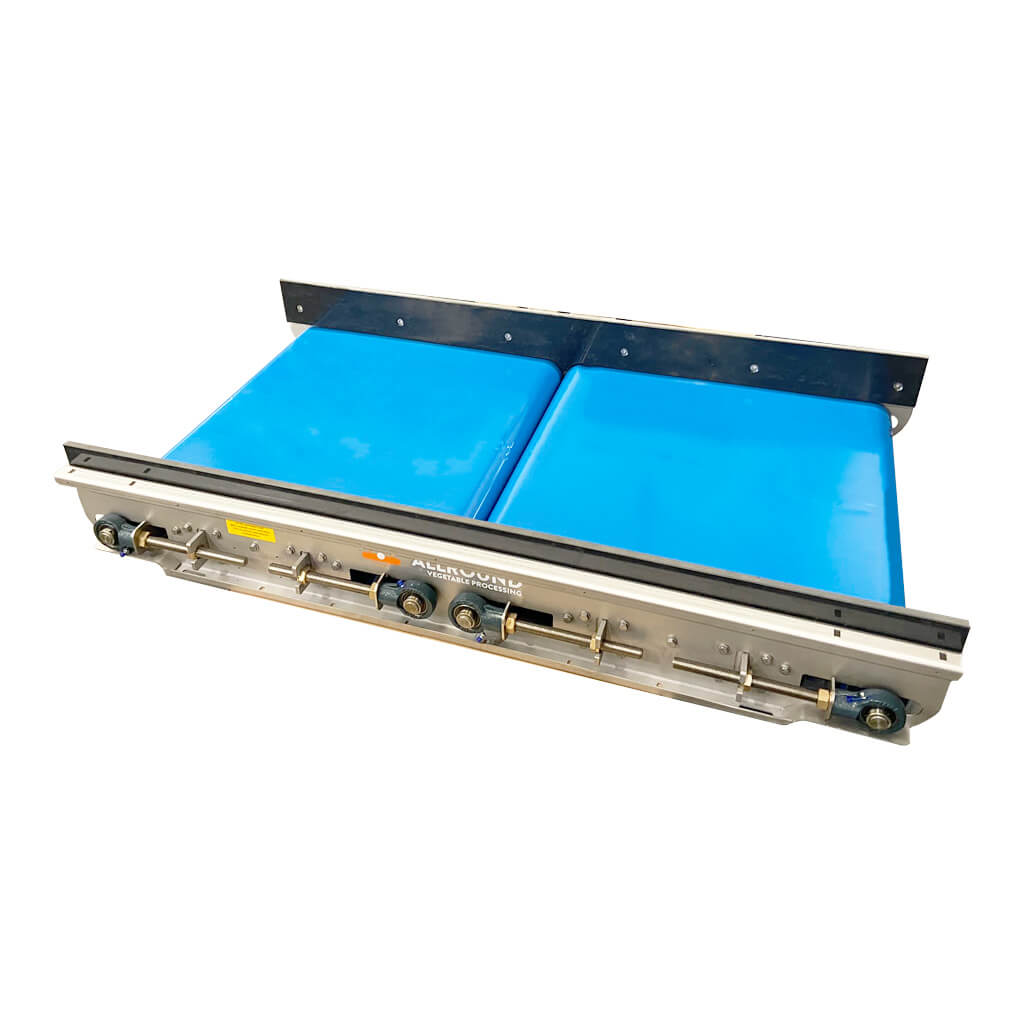

Transport belt

The Allround transport belts is designed to transport produce over longer distances. There are several variations

of belts. Each variation is intended for a different purpose.

Types and specifications

Options

Material and treatment (cover)

- Painted mild steelFrame is made from painted mild steel. The bearings and drive/idle rollers are from mild steel

- Stainless steelFrame is made from stainless steel. The bearings and drive/idle rollers are from mild steel

- Zinc plated steelFrame is made from zinc plated steel. The bearings and drive/idle rollers are from mild steel

Belt

- Intralox flush grid 400Passage of 17%

- Intralox flush grid 1100Passage of 28%

- Intralox flush grid 2400Passage of 42%

Electrical control

- No electricMotors only. Wiring, additional sensors and/or control panel are not included

- Stand-aloneMotors, necessary sensors, switch box and control box

- Central control in lineMotors and necessary sensors

Frequency inverter

- Speed adjustmentA frequency inverter is included to control the speed

Material and treatment (electrical panel)

- Painted mild steelThe electrical panel is made from painted mild steel

- Stainless steelThe electrical panel is made from stainless steel

Switch

- MaintenanceA maintenance switch is included

- ReverseA reverse switch is included

- Start/stopA start/stop switch is included

Extra motor

- 0.37 kWAn extra 0.37 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

- 0.75 kWAn extra 0.75 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

- 1.1 kWAn extra 1.1 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

- 1.5 kWAn extra 1.5 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

- 2.2 kWAn extra 2.2 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

- 3 kWAn extra 3 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)