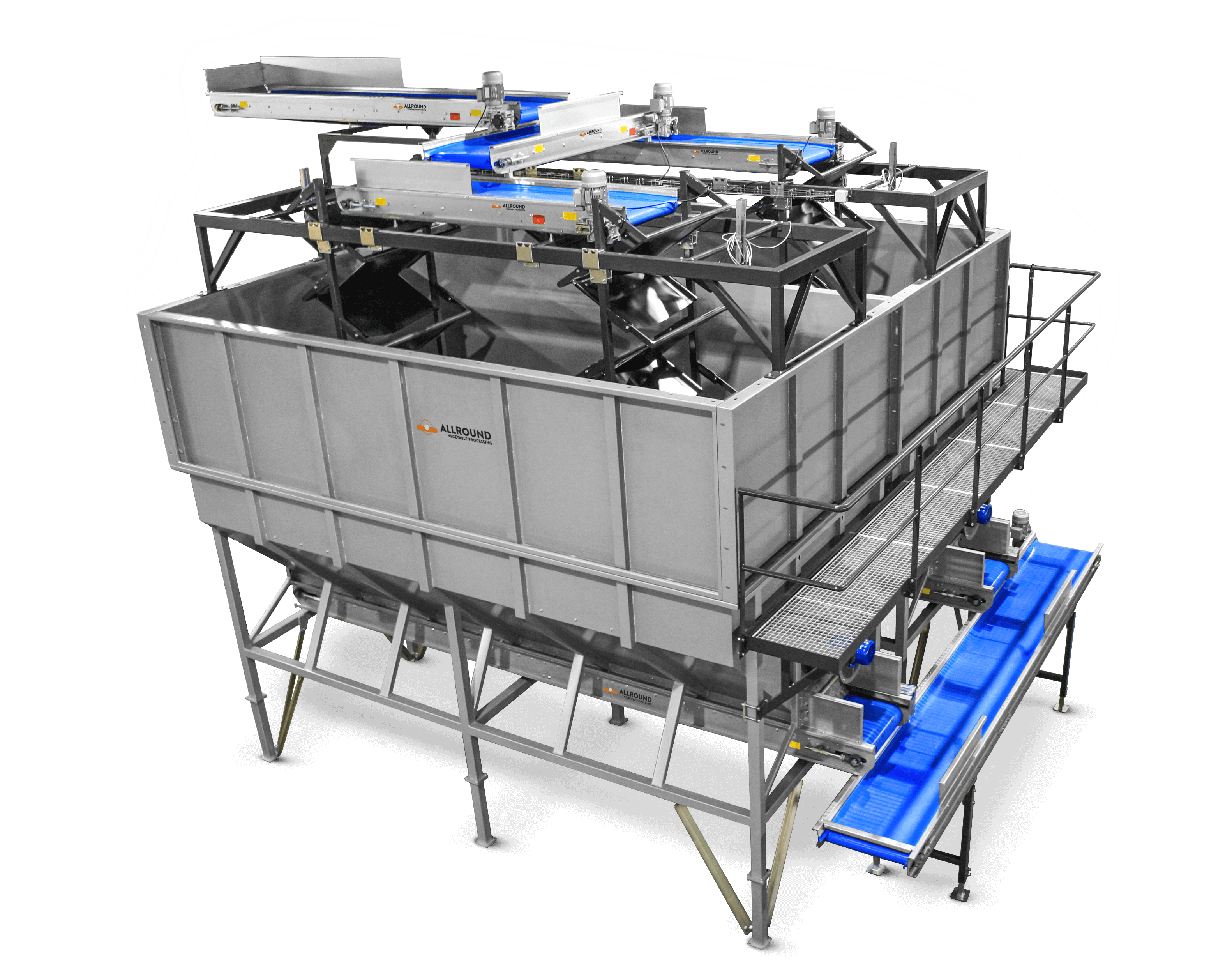

Allround storage hopper is designed to act as a buffer in a processing line, or between a processing line and a packaging line. The storage hopper will be gradually filled from the bottom to the top. An unloading conveyor is mounted at the bottom of the storage hopper, which can convey the produce out of the storage hopper. There’s a roof mounted over the unloading conveyor to reduce pressure over the unloading conveyor .

Soft landing is mounted at the bottom of the storage hopper. Placed under the zig-zag fall breaker or vertical filling belt to break the fall. A frequency inverter is included to control the speed, and a hatch is also mounted on the side of the machine. The hatch can be used for inspection/cleaning.

Storage hopper filling can be done via two methods: the zig zag fall breaker, which is normally used, and the moving vertical belt. The vertical filling belt is used for fresh produce where it is sensitive to damage. This belt starts filling the storage hopper from bottom to top by moving up and down to ensure complete filling of the storage hopper.

Characteristics

- Works on the principle of First in, First out (FIFO)

- Available in mild steel or stainless steel to suit various industry applications

- Real-time product tracking inside the storage hopper is possible

- Variable-speed transport conveyors ensure optimal flow to processing lines

- Soft landings ensure less product damage while filling

- Inspection hatch for manual checking

- Centralized control system

- Ventilators provide proper air circulation through the product to keep it fresh

Specifications

| Length of the machine (cm) | Width of the machine (cm) | Content available (m3) | |

|---|---|---|---|

| SH 250 | 250 | 250 | 4 |

| 250 | 250 | 10 | |

| 250 | 250 | 16 | |

| SH 300 | 300 | 250 | 5 |

| 300 | 250 | 11 | |

| 300 | 250 | 17 | |

| 300 | 300 | 13 | |

| 300 | 300 | 32 | |

| 300 | 300 | ||

| SH 400 | 400 | 250 | |

| 400 | 250 | 25 | |

| 400 | 250 | ||

| 400 | 300 | ||

| 400 | 300 | ||

| 400 | 300 | ||

| SH 500 | 500 | 250 | 8 |

| 500 | 250 | 20 | |

| 500 | 250 | 32 | |

| 500 | 300 | 9 | |

| 500 | 300 | 24 | |

| 500 | 300 | 40 | |

| SH 600 | 600 | 250 | 11 |

| 600 | 250 | 26 | |

| 600 | 250 | 40 | |

| 600 | 300 | 10 | |

| 600 | 300 | 28 | |

| 600 | 300 | 46 | |

| SH 700 | 700 | 300 | |

| 700 | 300 | 52 | |

| 700 | 300 |

Options

- Material and treatment (frame)

- Soft landing

- Outfeed height

- Electrical control

- Frequency inverter

- Material and treatment (electrical panel)

- Subframe on top

- Sensor

- Hatch

- Ventilator

- Towerlight