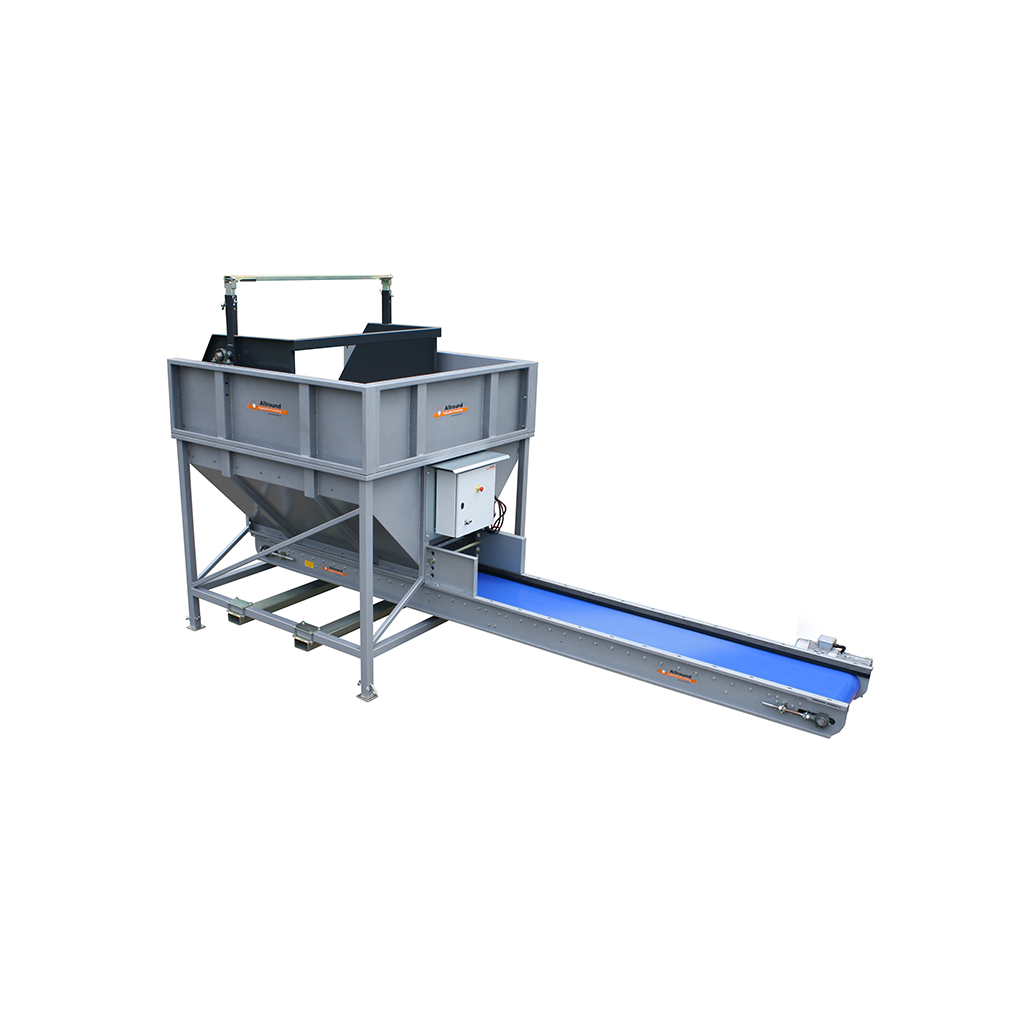

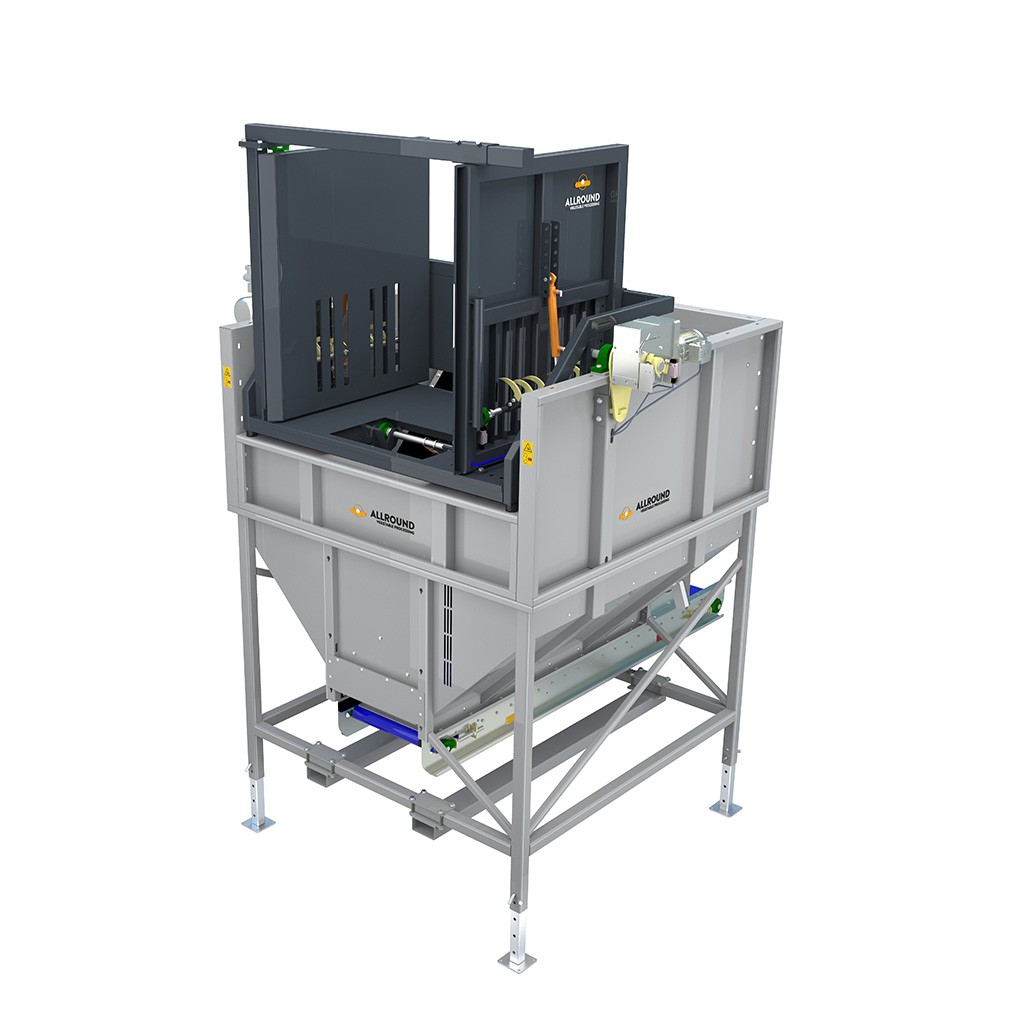

Storage hopper–box tipper combinations

The storage hopper with box tipper is designed to act as a buffer with tipping possibility. A box with produce is placed into the tipper. The box tips and the produce falls down into the storage hopper. An unloading conveyor is mounted at the bottom of the storage hopper, which can convey the produce out of the storage hopper.

Types and specifications

SHB 160-1.5

| Total width machine | 2170 mm |

| Total length machine | 2170 mm |

| Maximum box width | 160 |

| Content | 1.5 m³ |

SHB 160-3

| Total width machine | 2170 mm |

| Total length machine | 2170 mm |

| Maximum box width | 160 |

| Content | 3 m³ |

SHBB 160-3

| Total width machine | 2170 mm |

| Total length machine | 2170 mm |

| Maximum box width | 160 |

| Content | 3 m³ |

SHB 160-7

| Total width machine | 2170 mm |

| Total length machine | 2170 mm |

| Maximum box width | 160 |

| Content | 7 m³ |

SHB 180-3.5

| Total width machine | 2530 mm |

| Total length machine | 2530 mm |

| Maximum box width | 180 |

| Content | 3.5 m³ |

SHB 180-7

| Total width machine | 2530 mm |

| Total length machine | 2530 mm |

| Maximum box width | 180 |

| Content | 7 m³ |

Options

Radial graders come up with options that include brusher, electrical adjustment, rubber flap, rubber mat, size indication and safety switches. See More Images

Material and treatment (frame)

- Painted mild steel : Frame and plating is made from painted mild steel. The bearings and drive/idle rollers are from mild steel.

- Hot dipped galvanized : Frame is made from hot dipped galvanized steel. The bearings and drive/idle rollers are from mild steel. The plating is from stainless steel.

Electrical control

- Stand-alone : Motors, necessary sensors, switch box and control box.

Material and treatment (electrical panel)

- Painted mild steel : The electrical panel is made from painted mild steel.

- Stainless steel : The electrical panel is made from stainless steel.

Wireless remote control

- A wireless remote control is included. The machine can be controlled from a distance.

Safety fence

- Safety fences with a sensor are included. The sensor detects if someone walks between the fences and will stop the functioning of the machine.

Estimated capacity (tons/hour)

| 160-1.5 | 160-3 | 180-3.5 | 180-7 | |

|---|---|---|---|---|

| Potatoes, onions and red beet | 1.5 m³ | 3 m³ | 3.5 m³ | 7 m³ |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)