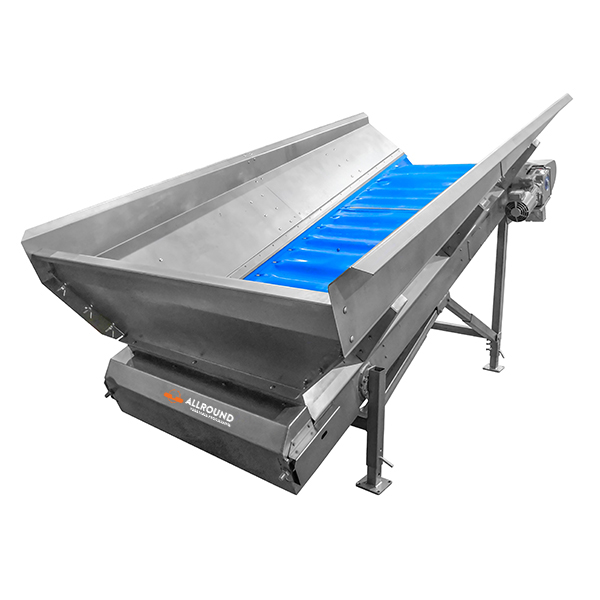

Hopper

Allround hoppers are designed to feed machines or product lines, or act as a buffer in a processing line. The hopper is designed to work with cubic boxes and big-bags. Because of the angle of the machine, the flow of product will always be even. Furthermore, a frequency inverter is fitted to the machine, to make sure the flow of product is always adjustable. The machine is extremely produce friendly, and the speed of the machine is adjustable.

Types and specifications

Options

Material and treatment (frame)

- Painted mild steelFrame is made from painted mild steel. The bearings and drive/idle rollers are from mild steel

- Stainless steelFrame is made from stainless steel. The bearings and drive/idle rollers are from mild steel

- Hot dipped galvanizedFrame is made from hot dipped galvanized steel. The bearings and drive/idle rollers are from mild steel. The plating is from stainless steel

Electrical control

- Stand-aloneMotors, necessary sensors, switch box and control box

- Central control in lineMotors and necessary sensors

- No electricMotors and necessary sensors only. Wiring, additional sensors and/or control panel are not included

Material and treatment (electrical panel)

- Painted mild steelThe electrical panel is made from painted mild steel

- Stainless steelThe electrical panel is made from stainless steel

Dosing function

- Dosing SensorA dosing sensor detects how much product is on the belt and adjusts the output rate of the hopper accordingly (automatic capacity control)

- Dosing millA dosing mill separates the sticking product and prevents the product from coming out in large numbers or not coming out of the machine at all

Wheels

- WheelsThe machine can be fitted with wheels, to make transportation of the machine easier

Estimated capacity (tons/hour)

| Total content (m³) | Effective content (m³) | |

|---|---|---|

| B 100-300 | 2 | 1,5 |

| B 120-450 | 5,5 | 3,5 |

| B 160-500 | 11 | 7 |

| B 230-800 | 20 | 14 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)